Sludge traps in high performance in heating and cooling installations

It is used to separate sediment and dirt.

The difference of the sediment holder compared to the classical sediment holders is the accumulation and discharge of dirt at the bottom of the device by filtering through the filter.

It is easily evacuated with the valve.

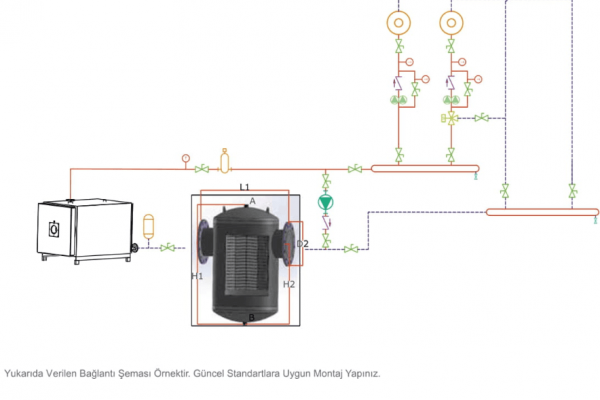

In heating systems, sediment traps must be in the return line.

It should be on the return line close to the chillers in cooling systems.

Capacity and Main Dimensions

|

Model |

Flow (m³/h) |

H1 (mm) |

H2 (mm) |

A (mm) |

B (mm) |

D2 (DN) |

L1 (mm) |

Flanged D2 (mm) |

Welding |

|

|

L1 (mm) |

L1 (mm) |

|||||||||

| WTT 50 | 9 | 620 | 370 | 3/4" | 1" | 50 | 350 | 350 | 2" | 260 |

| WTT 65 | 14 | 620 | 370 | 3/4" | 1" | 65 | 350 | 350 | 2 1/2" | 260 |

| WTT 80 | 21 | 650 | 430 | 3/4" | 1" | 80 | 470 | 470 | 3" | 365 |

| WTT 100 | 35 | 650 | 430 | 3/4" | 1" | 100 | 470 | 470 | 4" | 365 |

| WTT 125 | 54 | 825 | 435 | 3/4" | 1" | 125 | 640 | 640 | 5" | 525 |

| WTT 150 | 83 | 825 | 435 | 3/4" | 1" | 150 | 640 | 640 | 6" | 525 |