-In our tanks, replaceable type EPDM membrane tanks are used.

-Operating temperature -10°C-100°C (with the use of appropriate antifreeze at 10°C)

-Scratch, impact, corrosion resistant.

-It is necessary to start the return line in heating systems.

-Prevents calcification and corrosion, prolongs the life of the installation.

- When the heating water is heated under pressure, it provides an increase in efficiency and additional fuel savings.

- It prevents the formation of air in the installation.

-The problem of evaporation, freezing and drop in water level in open expansion tanks eliminates it.

Capacity:(tank volume) 24-5000L

Max conveying pressure: 10-16

Bar Factory pressure: 14 Bar

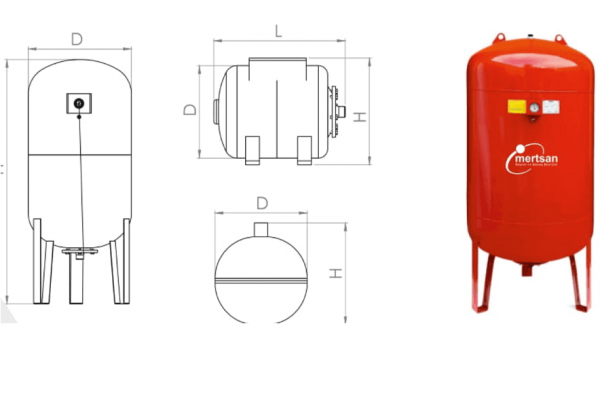

Capacity and Main Dimensions

|

Model |

Tank Volume |

Max. Operation Pressure (bar) |

Plant Exit Pre-gas Pressure (bar) |

Water Connection (inch / DN) |

Dimensions |

Approximate Weight (t) |

||

|

Diameter D (mm) |

Height H (mm) |

|||||||

|

Horizontal |

||||||||

| WE 24 | 24 | 10 | 1 | 1" |

D:265 L:370 |

310 | 4,6 | |

| WE 50 | 50 | 10 | 4 | 1" |

D:350x L:410 |

410 | 4,9 | |

| WE 60 | 60 | 10 | 4 | 1" |

D:350 x L:610 |

410 | 8,0 | |

| WE 80 | 80 | 10 | 4 | 1" |

D:425 x L:610 |

490 | 9,6 | |

| WE 100 | 100 | 10 | 4 | 1" |

D:425 x L:750 |

490 | 12,1 | |

|

Sphere |

||||||||

|

5 |

10 | 1 | 1/2" | 190 | 180 | 2,4 | ||

|

|

||||||||

|

5 |

10 | 4 | 1" | 350 | 480 | 4,5 | ||

|

Vertical |

||||||||

| WE 50 |

50 |

10 | 4 | 1" | 350 | 640 | 6,8 | |

| WE 60 |

60 |

10 | 4 | 1" | 350 | 720 | 7,8 | |

| WE 80 |

80 |

10 | 4 | 1" | 425 | 820 | 10,5 | |

| WE 100 |

100 |

10 | 4 | 1" | 425 | 1000 | 13 | |

| WE 150 |

150 |

10 | 4 | 1" | 570 | 1000 | 21,1 | |

| WE 200 |

200 |

10 | 4 | 1" | 570 | 1100 | 24 | |

| WE 300 |

300 |

10 | 4 | 1 1/4" | 630 | 1150 | 35 | |

| WE 500 |

500 |

10 | 4 | 1 1/4" | 740 | 1520 | 62 | |

| WE 750 |

750 |

10 | 16 | 4 | 2" | 800 | 1780 | 93 |

| WE 1000 |

1000 |

10 | 16 | 4 | 2" | 800 | 2200 | 115 |

| WE 1500 |

1500 |

10 | 16 | 4 | 2" | 950 | 2400 | 165 |

| WE 2000 |

2000 |

10 | 16 | 4 | 2" | 1100 | 2400 | 275 |

| WE 2500 |

2500 |

10 | 16 | 4 | 2 1/2" | 1200 | 2380 | 325 |

| WE 3000 |

3000 |

10 | 16 | 4 | 2 1/2" | 1200 | 2900 | 353 |

| WE 4000 |

4000 |

10 | 16 | 4 | DN80 | 1400 | 3000 | 530 |

| WE 5000 |

5000 |

10 | 16 | 4 | DN80 | 1500 | 3000 | 610 |